Description

Gantry Saw HBP1500-1800 GANTRY

The ultimate cutting machines for cast blocks or freeform forgings. Found in forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines excel in handling large dimensions. They're perfect for preproduction in tool and mold making factories, efficiently saving valuable milling time.

Servo Feed System

The BEHRINGER servo feed system with cutting pressure control produces constant chip removal, especially with slow feed movements. Large and difficult-to-cut materials are thus sawn with the highest cutting performance and at the same time longer blade life.

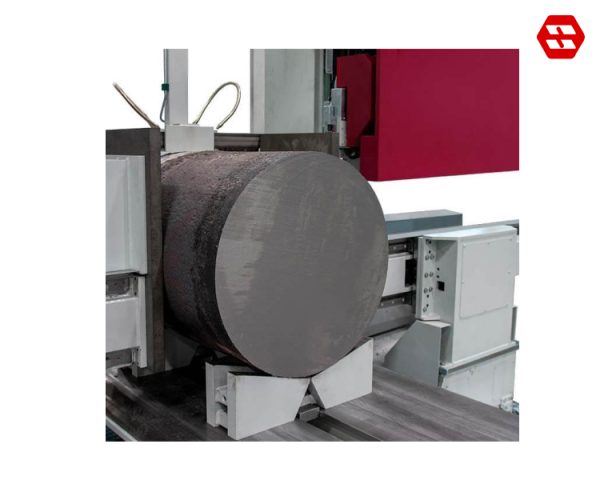

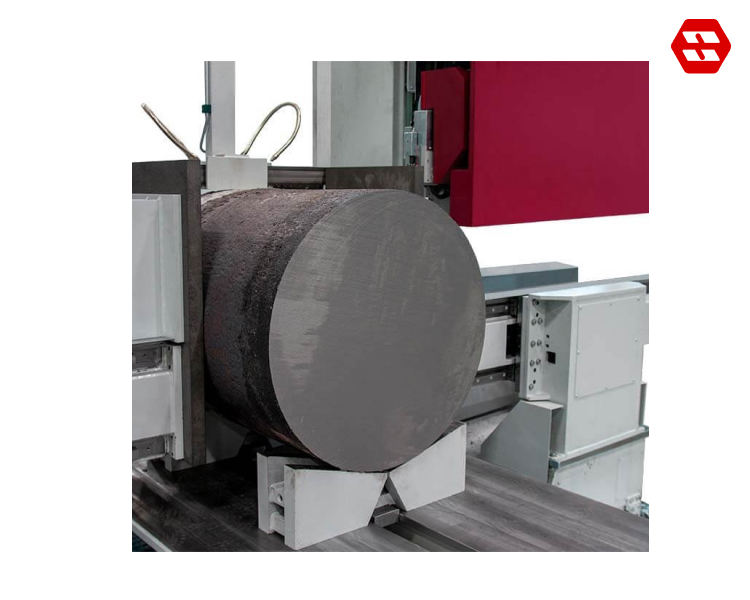

Centric Material Clamping

The material clamping vices and blade guide arms can be traversed independently of each other. The material is clamped in the position in which it was placed on the table, without the need for it to be moved to meet the fixed side of a vice.

Gantry With Two or More Saw Units

Special offering from BEHRINGER: the Gantry with two or more saw units. This innovative solution enhances cutting efficiency by incorporating multiple saw units into a single gantry system. Ideal for high-volume production environments, this configuration maximizes throughput while maintaining precision and reliability.

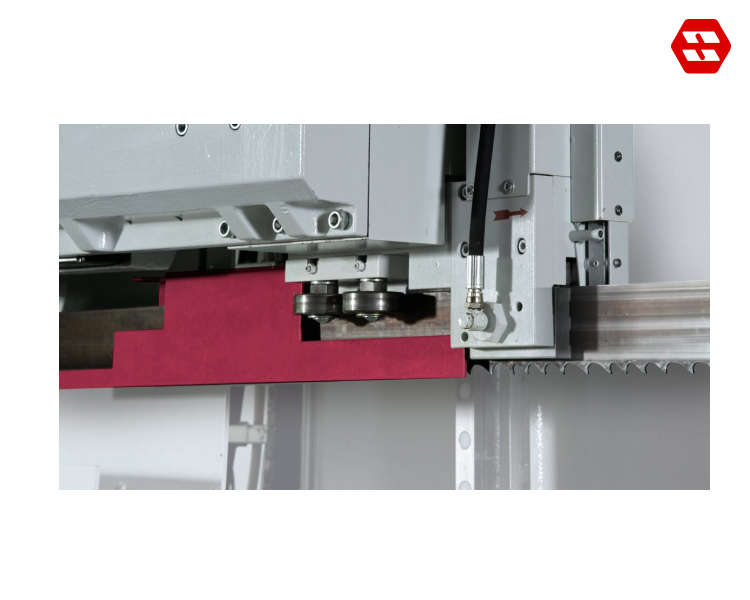

Cast Iron Band Guiding Parts

Cast iron band guiding parts are essential components in bandsaw machinery, providing stability and precision during cutting operations. Renowned for their durability and heat resistance, these components ensure accurate alignment and smooth movement of the bandsaw blade..

Carbide Blade Guides

Carbide blade guides represent the pinnacle of precision and durability in bandsaw blade guidance. Crafted from high-quality carbide materials, these guides offer exceptional wear resistance and thermal stability, ensuring prolonged performance even in demanding cutting environments. .

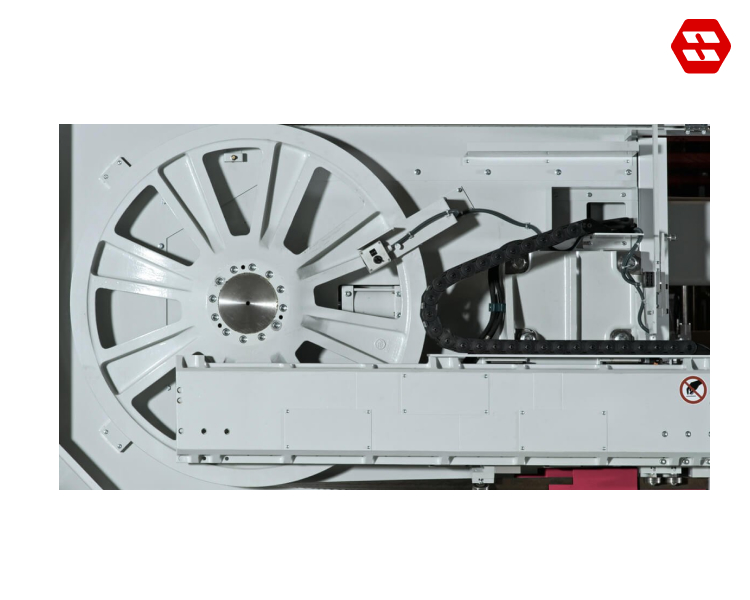

Powerful Saw Drive

A powerful saw drive is the beating heart of any cutting operation, providing the force necessary to swiftly and accurately slice through materials. Renowned for their robustness and reliability, these drives deliver high torque and speed, ensuring efficient and precise cuts in a variety of industrial settings.

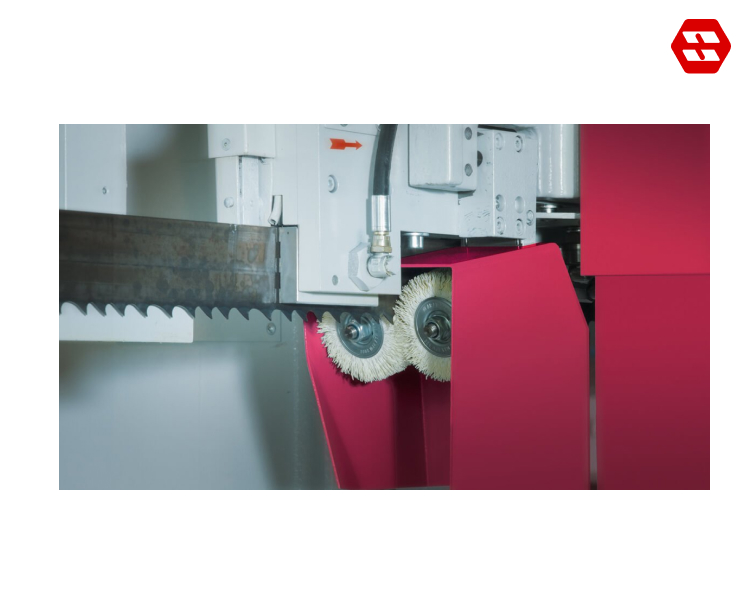

Duplex Chip Brushes

Duplex chip brushes are essential tools for efficient chip removal in machining operations. Featuring dual brush heads, these tools effectively sweep away debris and chips from workpieces and machinery, ensuring cleanliness and preventing damage.

Features of The Gantry Saw HBP1500-1800 GANTRY

Simplified Material Handling.

The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling.

Strong Saw Drive.

BEHRINGER large band saws feature a high-torque frequency controlled saw drive with heavyduty hollow shaft gearbox. Drives with different speed ranges are available to suit particular materials.

Powered Duplex Chip Brushes

Actively clean the blade and prevent chips being drawn into the cutting channel.

Optimum Accessibility.

BEHRINGER attaches great importance to the aspect of maintenance and servicing: All the important parts and components are very accessible.

Centric Material Clamping.

The optimum solution for bulky material. The material clamping vices and blade guide arms can be traversed independently of each other.

Precise Guiding System in Portal Design.

The portal design of the machine concept is the most recognizable feature of the BEHRINGER large band saws.

Automation Possible.

BEHRINGER large bandsaws in the Gantry design can be upgraded to an automated sawing system.

Technical Data Gantry Saw HBP1500-1800 GANTRY

| Cutting Range | |

| Cutting range 90° round | 1,500 mm |

| Cutting range 90° flat | 1,800 x 1,500 mm |

| Smallest dimension to be sawn round | 400 mm |

| Smallest dimension to be sawn flat | 400 x 50 mm |

| Performance Characteristics | |

| Drive power | 15 kW |

| Blade speed | 8 – 84 m/min |

| Saw blade dimensions | 14,830 x 80 x 1.6 mm |

| Total power | 30 kW |

| Table size L x W | 6,500 x 1,500 mm |

| Travel way of the portal (horizontal) | 5,000 mm |

| ravel way of the portal (vertical) | 1,600 mm |

| Dimensions and Weight | |

| Length | 11,600 mm |

| Width | 7,800 mm |

| Height | 4,200 mm |

| Weight | 33,000 kg |