Description

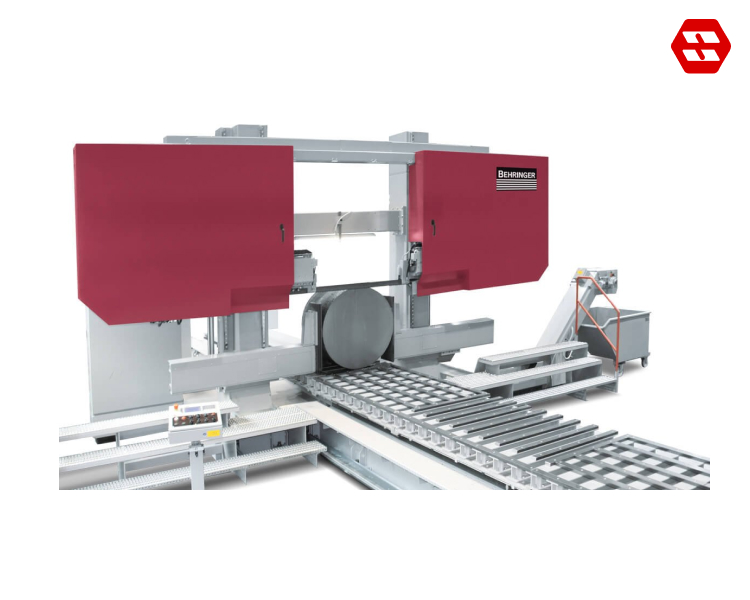

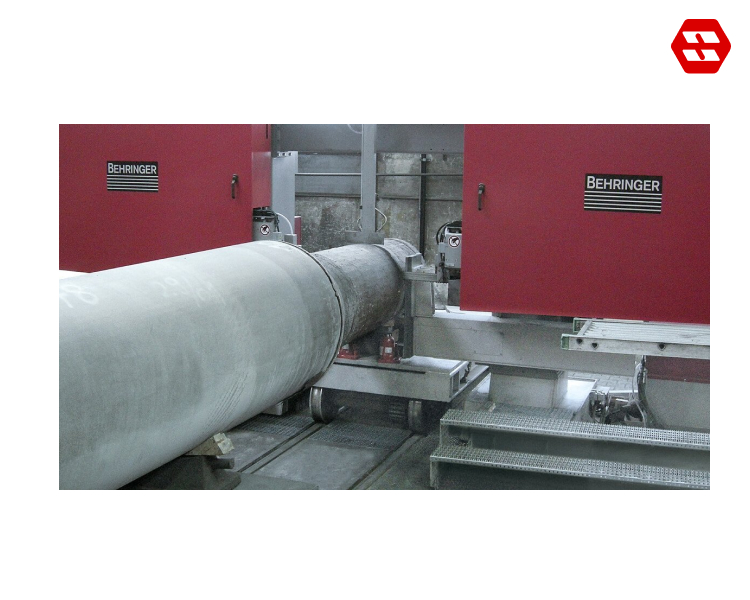

Table Bandsaw HBP1500-1800T

The optimum solution for materials with a wide range of geometries. Ideal for forges, rolling mills, die casting factories, steel finishing works, and tool and mold making, this horizontal bandsaw boasts a table design that enhances versatility.

Servo Feed System

The BEHRINGER servo feed system with cutting pressure control produces constant chip removal, especially with slow feed movements. Large and difficult-to-cut materials are thus sawn with the highest cutting performance and at the same time longer blade life.

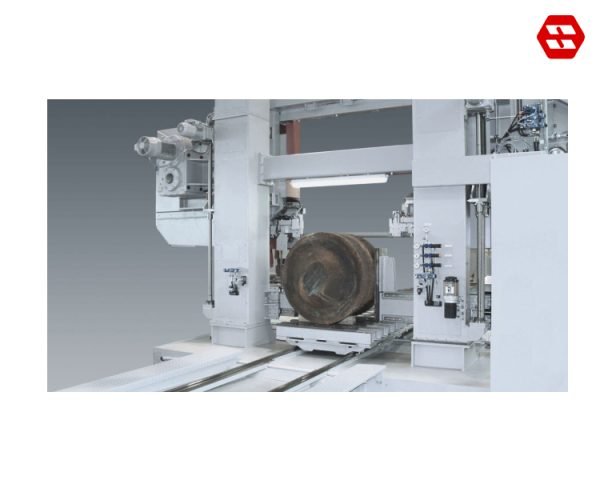

Solid Material Support Table

Solid Material Support Table, an essential accessory for bandsaw machines. Designed to provide stable and reliable support for workpieces during cutting operations, this table ensures precise and accurate cuts.

Optimum Accessibility For Maintenance

BEHRINGER attaches great importance to the aspect of maintenance and servicing: All the important parts and components are very accessible. The open design offers direct access to all wearing parts, optimizing both maintenance and repairs and simplifying saw blade changes.

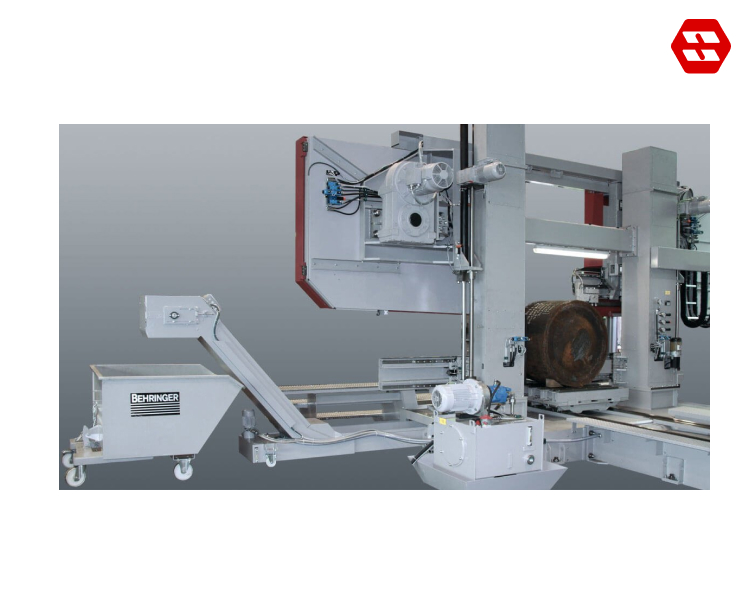

Chip Conveyor With Integrated Coolant tank

Conveyor with Integrated Coolant Tank, a versatile solution for efficient chip removal in machining operations. This innovative system combines chip conveying with coolant storage, streamlining the process and maximizing space utilization on the shop floor.

Large Bandsaw With Split Machine Base For Trolley Application

This innovative bandsaw features a split base configuration, allowing easy access for trolley loading and unloading. Ideal for handling heavy workpieces in industrial settings, its robust construction ensures stability and precision during cutting operations.

Cast Iron Band Guiding Parts

Crafted from durable cast iron, these guiding parts ensure precise alignment and stability of the bandsaw blade during cutting operations. Renowned for their durability and resistance to wear, they provide reliable support and help maintain accurate cuts over time.

Powerful Saw Drive

Engineered for high performance, this drive system delivers the necessary torque and speed to efficiently cut through various materials with precision. Renowned for its robustness and reliability, the powerful saw drive ensures smooth and consistent cutting operations, even under heavy loads.

Features of The Table Bandsaw HBP1500-1800T

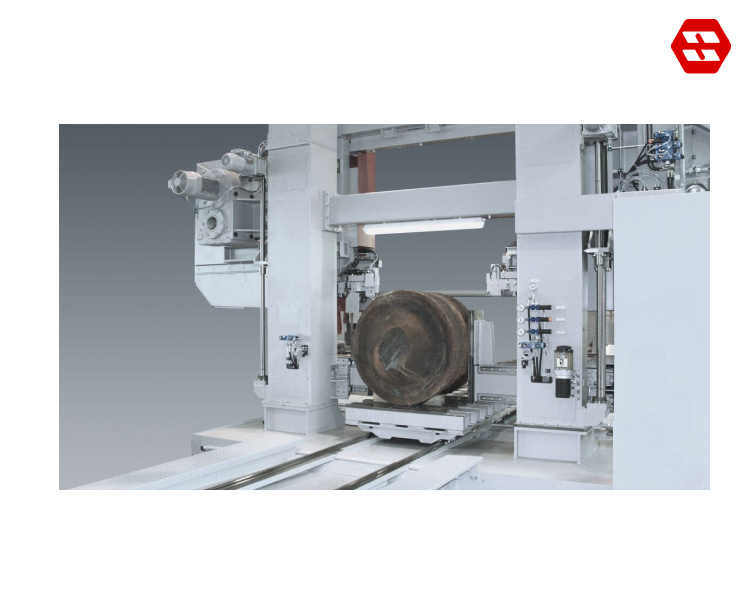

Centric Material Clamping.

The optimum solution for bulky material. The material clamping vices and blade guide arms can be traversed independently of each other.

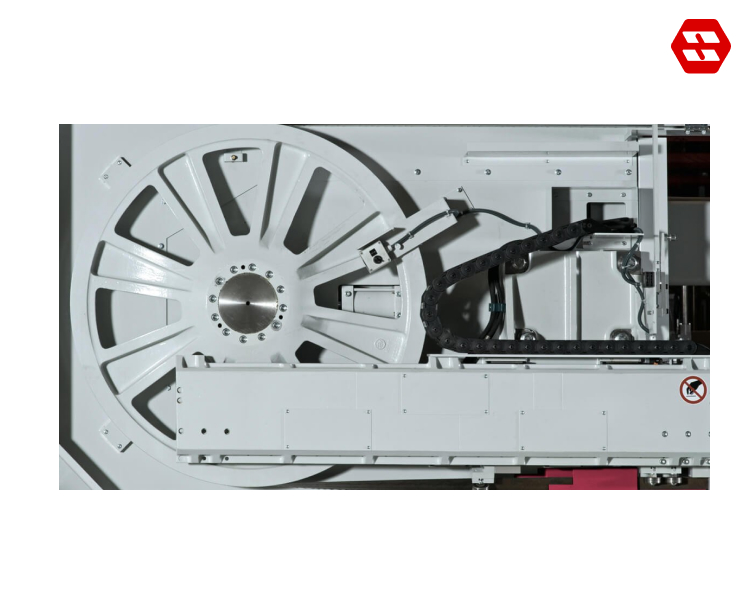

Servo Feed System With Two Ball Screw Spindles.

The BEHRINGER servo feed system with cutting pressure control produces constant chip removal, especially with slow feed movements.

No Foundation Work Necessary.

The system is installed on the existing hall floor. Expensive foundation work is not necessary.

Precise Guiding System in Portal Design.

The portal design of the machine concept is the most recognizable feature of the BEHRINGER large band saws.

Optimum Accessibility.

BEHRINGER attaches great importance to the aspect of maintenance and servicing: All the important parts and components are very accessible.

Automation Possible.

BEHRINGER table machines are supplied as semi-automatic machines as standard. Automation is possible by upgrading with an additional vice at the end of the table.

Powered Duplex Chip Brushes.

Actively clean the blade and prevent chips being drawn into the cutting channel.

Technical Data Table Bandsaw HBP1500-1800T

| Cutting Range | |

| Cutting range 90° round | 1,500 mm |

| Cutting range 90° flat | 1,800 x 1,500 mm |

| Smallest dimension to be sawn round | 400 mm |

| Smallest dimension to be sawn flat | 400 x 200 mm |

| Performance Characteristics | |

| Drive power | 15 kW |

| Blade speed | 8 – 84 m/min |

| Saw blade dimensions | 15,430 x 80 x 1.6 mm |

| Total power | 30 kW |

| Table size L x W | 3,000 x 1,200 mm |

| Maximum table load | 30,000 kg |

| Dimensions and Weight | |

| Length | 6,000 mm |

| Width | 8,100 mm |

| Height | 4,500 mm |

| Weight | 17,000 kg |

| Material support height | 700 mm |