Description

3D Saw LPS-T 3D 1200

The LPS-T 3D 1200 vertical bandsaw is tailored for precise cutting of additively manufactured components, accommodating printing plates up to 1,200 x 1,200 mm in size. With a movable support table and NC-controlled workpiece holding, even heavy printing plates can be effortlessly managed using lifting equipment.

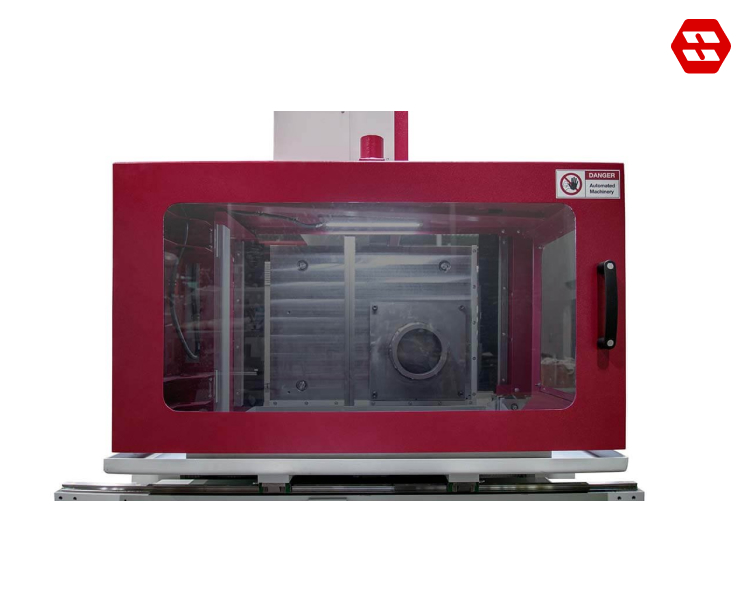

Maschinenumhausung

The "Maschinenumhausung," a protective housing designed to encase machinery, enhancing safety and operational efficiency in industrial settings.

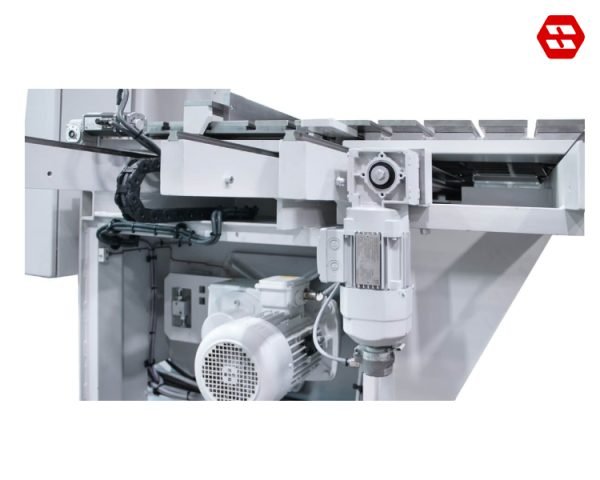

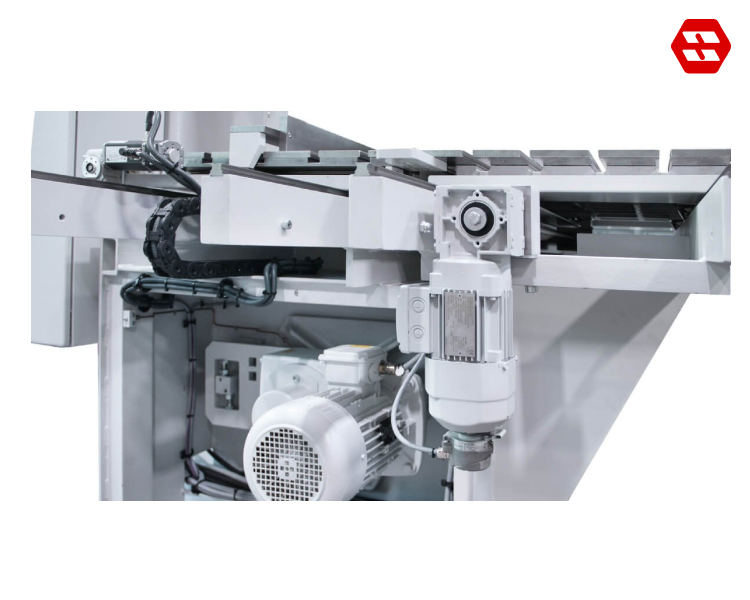

Vorrichtung Mit NC-Positionierung

Introducing the NC-positioning device, a cutting-edge tool enabling precise positioning control for enhanced accuracy and efficiency in machining operations.

Höchste Präzision

Experience unparalleled precision with our cutting-edge technology.

Kühlmittelfilter

The coolant filter, an essential component designed to remove contaminants from coolant fluids, ensuring optimal performance and longevity of machinery in industrial applications.

Intuitive Touch Steuerung BehrCtrl10

Introducing BehrCtrl10, an intuitive touch control system designed by BEHRINGER for seamless operation and enhanced user experience in industrial settings.

Tischpositionierung über Kugelrollspindel

Introducing table positioning via ball screw spindle, a precise and efficient method for adjusting the position of workpieces on industrial machinery.

Features of The 3D Saw LPS-T 3D 1200

Quick and Easy Loading and Unloading.

The shortest possible setup times are achieved because the HBE320-523 3D is equipped with a device for holding additively printed base plates.

Unsurpassed Precision and Cutting Performance.

The high cutting accuracy, quiet running and long blade life are all down to the special torsion resistant design of the saw frame.

Movable Material Support Table.

For easy loading and unloading by crane, the material table of the vertical saw can be moved out from under the saw unit.

Automatic Positioning of The Printing Plate.

After mounting the 3D base plate, the alignment to the saw band is fully automatic. After entering the plate thickness in the control, an NC axis positions the device to the sawing line.

Quick Bandsaw Blade Change.

Quick and easy – tool-free bandsaw blade changes mean shortest set-up times. Just a few simple steps are all that is needed to change the bandsaw blade of the block saw.

Coolant Cleaning.

A standard filter unit cleans the coolant from particles and powder residues that are released during the sawing of printed components.

Powered Duplex Chip Brushes.

Actively clean the blade and prevent chips being drawn into the cutting channel. The brushes are adjusted automatically towards the saw blade, ensuring uniform cleaning action.

Servo Feed System With Cutting Pressure Control.

The BEHRINGER servo feeding system ensures constant chip removal and makes better use of the capabilities of modern bandsaw blades.

Compact.

Due to its compact dimensions, the table band saw LPS-T 3D 1200 can also be set up in constricted spaces.

Technical Data 3D Saw LPS-T 3D 1200

| Cutting Range | |

| Maximum printing plate size flat W x H | 1,200 x 1,200 mm |

| Minimum printing plate size flat W x H | 300 x 300 mm |

| Maximum print height | 650 mm |

| Minimum plate thickness | 20 mm |

| Performance Characteristics | |

| Drive power | 4 kW |

| Blade speed | 17-120 m/min |

| Saw blade dimensions | 7,300 x 54 x 1.6 mm |

| Total power | 6 kW |

| Printing plate positioning | Servo motor via ball screw |

| Dimensions and Weight | |

| Length | 4,250 mm |

| Width | 3,450 mm |

| Height | 4,150 mm |

| Weight | 4,000 kg |

| Material support height | 1,200 mm |