Description

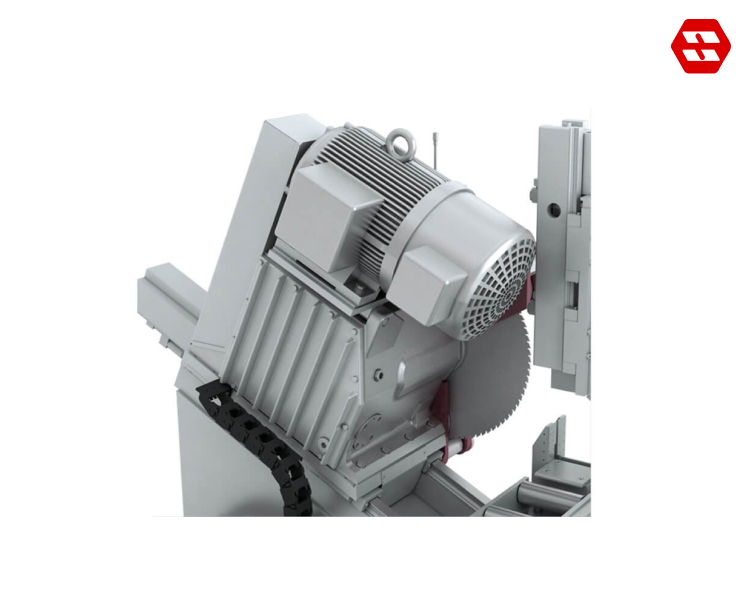

High Speed Circular Saw HCS 100 MF

Whether for fabrication or manufacturing, the HCS 100 MF sets the standard for efficiency and reliability in metalworking. Elevate your productivity and precision with the cutting-edge capabilities of the HCS 100 MF Circular Saw Machine.

Stable,Low-Vibration Gearbox

Our machinery is equipped with a Stable, Low-Vibration Gearbox, designed to enhance both performance and precision in demanding industrial environments. This advanced gearbox minimizes vibrations significantly, ensuring smoother operations and higher quality cuts with reduced noise levels.

Powerful Control System

Harness unprecedented precision and efficiency with the Powerful Control System of the Circular Saw Machine High Speed HCS 100 MF by BEHRINGER. Engineered to provide comprehensive command over cutting operations, this advanced system allows for intricate adjustments and real-time monitoring, ensuring optimal performance.

Funnel-Shaped Machine Base

Ensures perfect chip flow into the chip conveyor as well as the speedy disposal of chips and cooling liquids. Cleaning is extremely easy.

Servo-Driven Feeding Gripper

Swiftly positions the material precisely and in a matter of seconds. Its advantages are: accurate cutting length and short cycle times with tight tolerances.

Features of The High Speed Circular Saw HCS 100 MF

Robust,Low-Vibration Gear Unit.

The heart of the saw unit is the worm gear unit, made by BEHRINGER EISELE. It is heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface and the blade life.

Extremely Solid Construction.

The extremely stable and solid machine bed is the basis of every HCS high speed circular saw. It ensures excellent vibration damping and ideal power flow.

Short Cycle Times.

by electronic cutting height adjustment and rapid return of the saw blade.

Simple and Intuitive Operation of The Control Unit.

Everything under control! The control unit is self explanatory and easy to operate; operating mistakes are avoided and it allows for quick navigation within the program menu.

Chip Conveyor With Coolant Tank.

The new chip conveyor houses the coolant tank and coolant pump saving space. It ensures a rapid removal of the sawing chips and is easy to clean and maintain.

Multi-Fluid Cooling System.

Micro-spraying devices for minimal lubrication, and cooling vortex tubes for dry processing.

BVA - Blade Vibration Absorber.

The optimal synergy between the generously-sized carbide metal guides and an efficient brush system guarantees not only extended service life but also enhances cutting precision and efficiency.

Linear Guided Saw Feed.

The saw unit is moved dynamically through the entire cutting area via two linear guides in conjunction with a ball screw and a servo motor.

Funnel-Shaped Machine Base.

Provides a perfect chip flow into the chip conveyor as well as the speedy disposal of chips. Cleaning is extremely easy.

Technical Data High Speed Circular Saw

HCS 100 MF

| Cutting Range | |

| Cutting range 90° round | 105 mm |

| Cutting range 90° square | 90 x 90 mm |

| Smallest dimension to be sawn round | 20 mm |

| Smallest dimension to be sawn square | 20 x 20 mm |

| Performance Characteristics | |

| Drive power | 22.5 kW |

| RPM | 20 – 250 min-1 |

| Saw blade diameter | 285 / 315 / 360 mm |

| Feeding length single stroke | 1,000 mm |

| Feed rate | 1,730 mm/s |

| Saw feed | servo-driven |

| Material clamping | hydraulic |

| Saw drive | servo-driven |

| Dimensions and Weight | |

| Length | 2,700 mm |

| Width | 2,400 mm |

| Height | 2,500 mm |

| Weight | 3,900 kg |

| Material support height | 1,170 mm |