Description

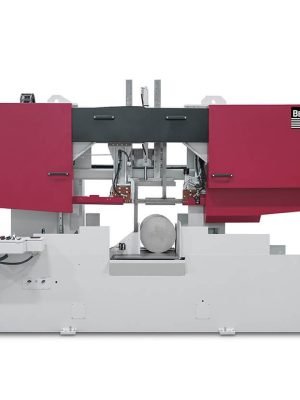

SHARK 660 CNC HS 4.0

SHARK 660 CNC HS 4.0, dual-column electromechanical automatic band sawing machine for 0° cuts of structural, stainless and alloy steels, solids and profiles. In addition to the automatic cutting cycle, it can also operate in semi-automatic mode.

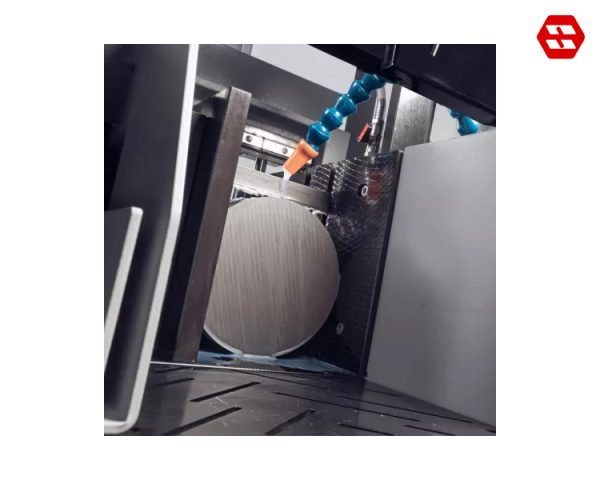

Motion of The Saw Head on Linear Guides

Motion of the saw head powered by two brushless motors for an auto-check of all data set/recorded so as to adjust cutting parameters in real-time, and Ø 32mm ball bearings screw nut to ensure a mechanical vibration reduction during the cut.

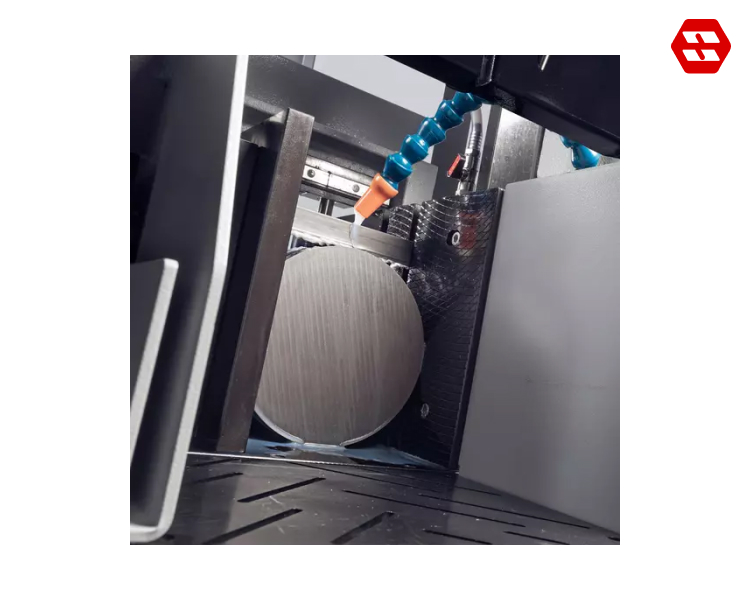

Adaptive Saw Head Down Feed Rate

Self-regulation in real-time of head down feed rate according to type of material or blade wear.

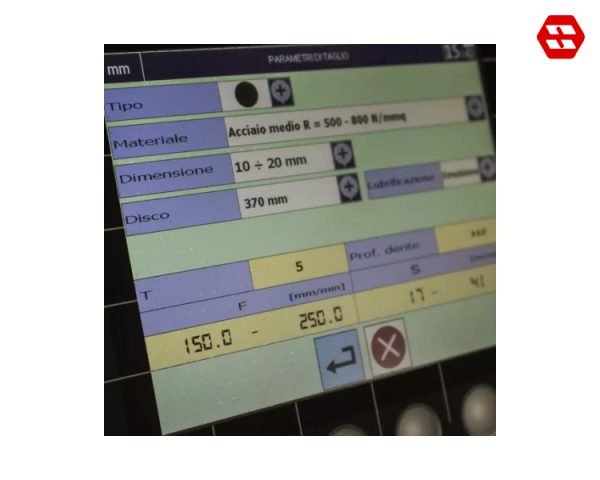

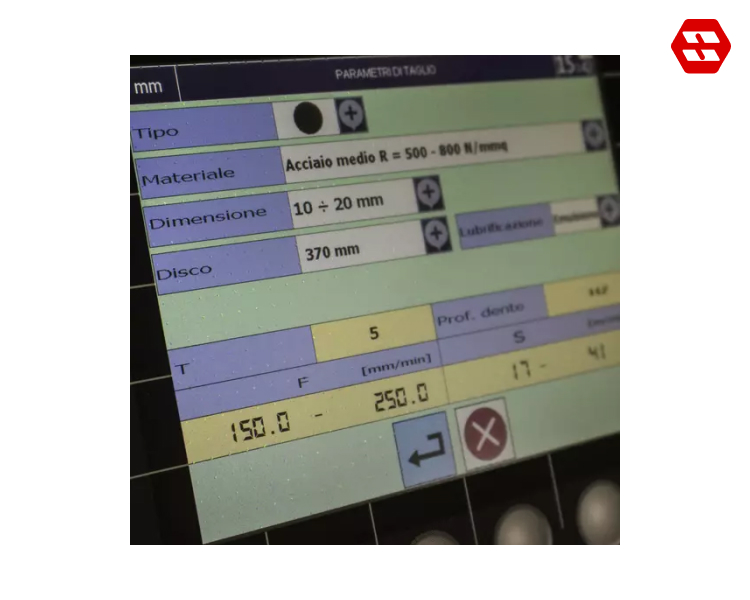

Material Library for The Automatic Setting of The Blade Rotation Speed And Head Down Feed Rate

From the extendable material library, you can choose the type and the geometry of the material, the hardness and the type of blade. Accordingly, the control sets the right blade speed and head down feed rate.

Floating Bar Feeder Vice

The bar feeder vice is self-aligning in order to feed even non-straight bars.

Industry 4.0 Ready-IOT

The optional IOT allows to maximize data collection and use them in favor of a better sawing machine cutting performance and longer blade life.

Technical Data Bandsaw Machine Semi Automatic

SHARK 660 CNC HS 4.0 MEP

CUTTING RANGE

| 0° | 660 mm | 660 mm |

PERFORMANCE CHARACTERISTICS

| Max. vice opening | 670 mm |

| Minimum cutting length | 10 mm |

| Rest piece no longer feeded | 70 mm |

| Band size | 8400 x 54 x 1.6 mm |

| Blade motor power | 15 Kw – Three-phase |

| Blade rotation speed | 15 ÷ 200 m/min |

| Inverter power | 22 – 47 Kw/A |