Description

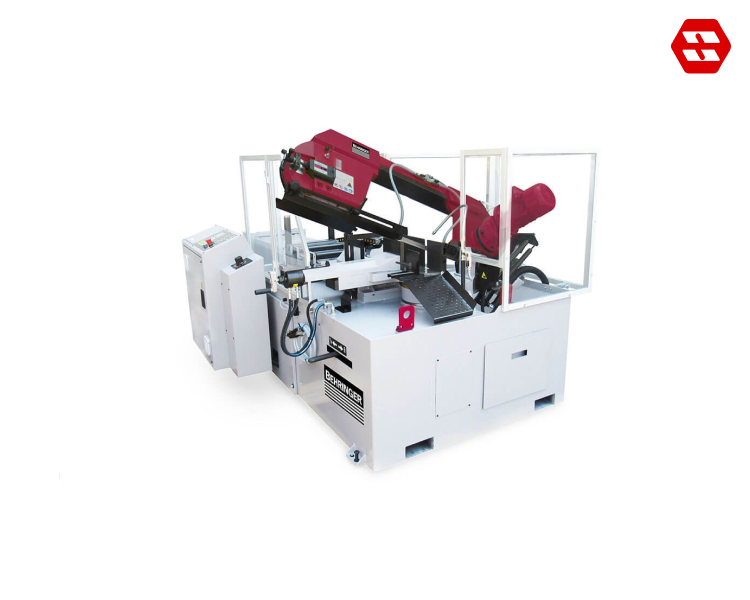

Automatic Bandsaw With Mitre Device SLB240AG

In addition to its extensive basic equipment, the automatic bandsaw offers an attractive price/performance ratio. The small footprint makes it the ideal sawing machine in metalworking stores.

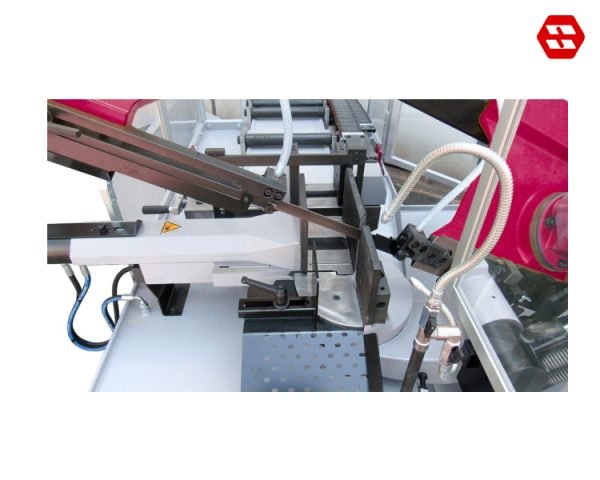

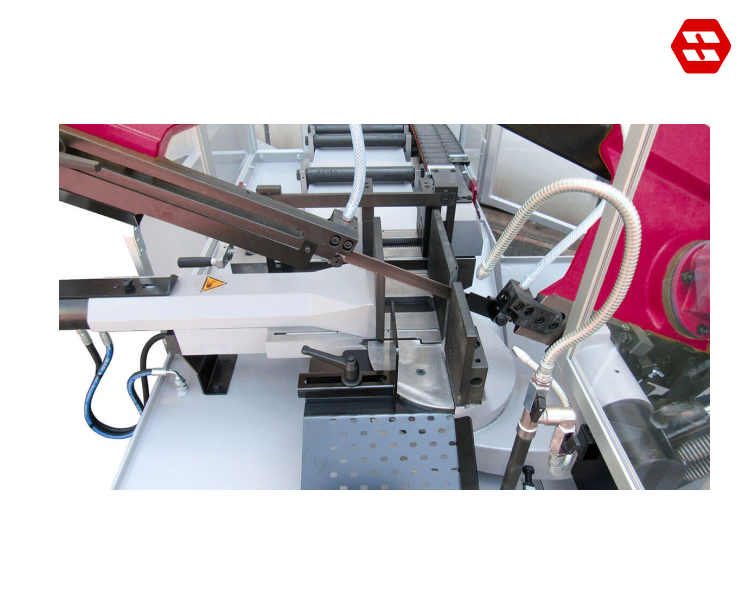

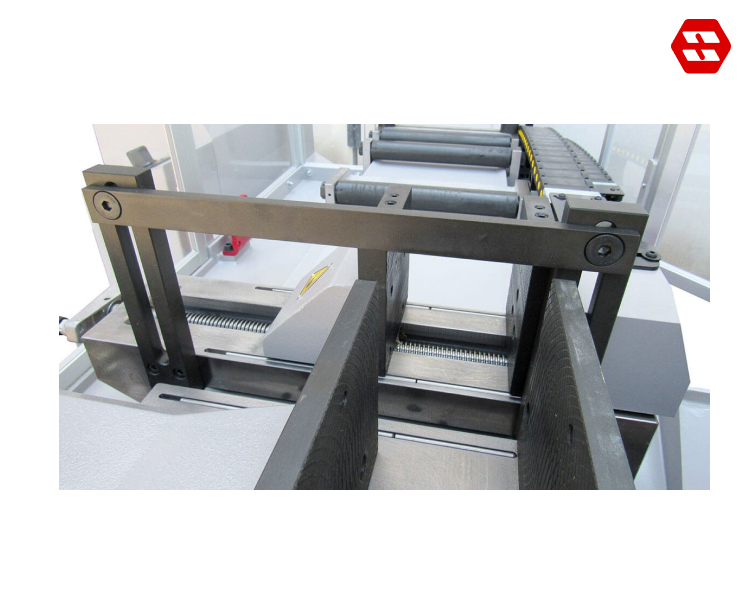

Material Clamps and Mitre Device

Material clamps and a mitre device, essential components designed to securely hold workpieces at precise angles for accurate cutting in industrial applications.

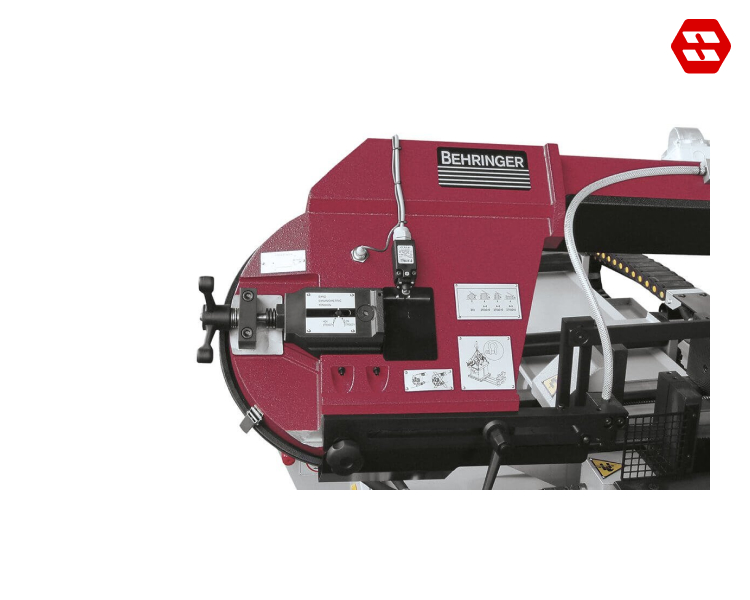

Saw Band Tensioning

The saw band is tensioned manually. The setting of the correct tensioning force is displayed optically. In order to prevent overloading during the sawing process, the pressure is equalized by means of a pretensioned disc spring package.

Control Panel

The Control Panel, a centralized interface facilitating the operation and management of industrial machinery for enhanced efficiency and productivity.

Automatic Material Feed

Automatic material feed, a feature designed to streamline the process of feeding materials into machinery, enhancing efficiency and productivity in industrial operations.

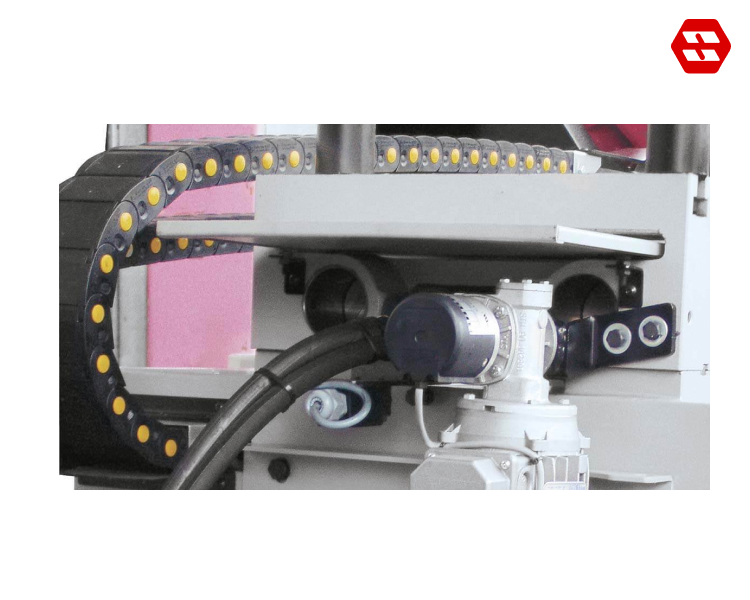

Material Feeding Gripper

The material feeding gripper, an essential component designed to securely grip and feed materials into machinery for efficient processing in industrial applications.

Features of The Automatic Bandsaw SLB240AG

Robust Material Vice With Quick-Clamping Device.

The material is clamped by a robust vice with a hydraulic quick-clamping device. The vice is adjusted to the material width using a handwheel.

NC Program Control.

Modern programmable logic controller with clear masks on the LCD display for simple and safe manual and automatic operation.

Miter Adjustment.

The miter angle can be adjusted to one side. The saw frame is locked by means of a quick-release clamp.

Frequency-Controlled Saw Drive.

Offers maximum flexibility when sawing different material grades such as stainless steel or aluminum.

Precise Band Guides.

Combination of roller and carbide guide of the saw band. Adjustment of the movable band guide according to the cutting width.

Saw Band Tensioning.

The saw band is tensioned manually. The setting of the correct tensioning force is displayed optically.

Hydraulic Saw Feed.

The saw feed is hydraulically controlled with an infinitely adjustable feed rate. The lifting and lowering of the saw frame is controlled by push buttons.

Coolant System.

The machine is equipped with 2 regulated coolant nozzles. The coolant tank can be removed for easy cleaning.

Technical Data Automatic Bandsaw SLB240AG

| Cutting Range | |

| Cutting range 90° round | 260 mm |

| Cutting range 90° flat | 310 x 260 mm |

| 45° Miter right round | 260 mm |

| 45° Miter right square | 260 x 260 mm |

| 45° Miter right flat | 290 x 120 mm |

| 30° Miter right round | 180 mm |

| 30° Miter right square | 180 x 180 mm |

| 30° Miter right flat | 190 x 90 mm |

| Smallest dimension to be sawn round | 10 mm |

| Smallest dimension to be sawn flat | 10 x 6 mm |

| Performance Characteristics | |

| Feeding length single stroke | 510 mm |

| Drive power | 1.5 kW |

| Blade speed | 16 – 120 m/min |

| Saw blade dimensions | 3,300 x 27 x 0.9 mm |

| Rest piece length in automatic mode (90°) | 80 mm |

| Shortes cutting length | 10 mm |

| Saw feed | hydraulic |

| Material feed | hydraulic |

| Dimensions and Weight | |

| Length | 2,550 mm |

| Width | 1,850 mm |

| Height | 1,700 mm |

| Weight | 1,160 kg |

| Material support height | 850 mm |