Description

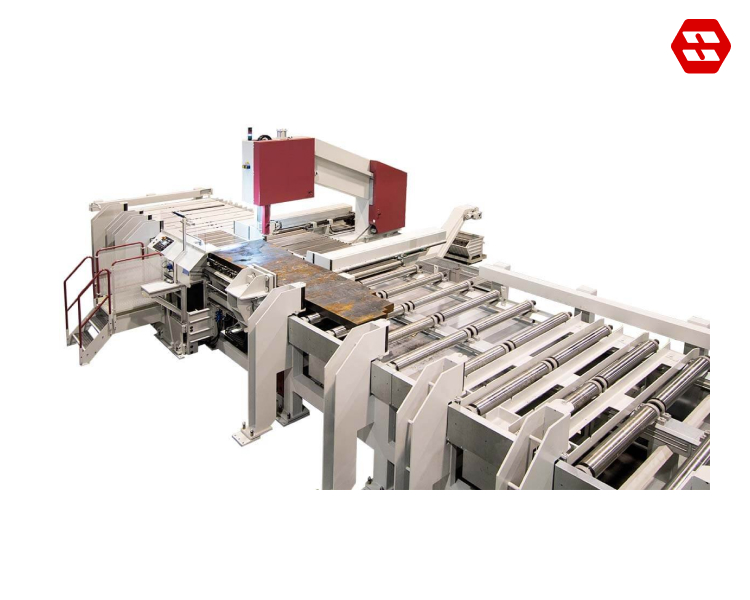

Automatic Plate Saw VPS60-160A

BEHRINGER VPS60-160A Automatic Plate Saw, engineered for the highest efficiency in cross-cutting plates and blocks. This cutting-edge solution offers fully automatic operations, optimizing productivity for large-scale tasks. Its vertical saw band arrangement provides clear advantages, offering higher cutting capacities and reducing tool costs.

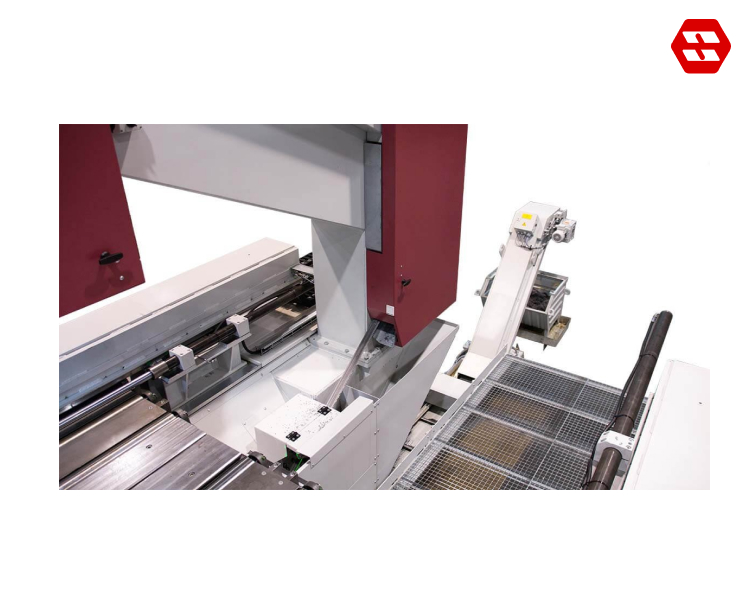

High-Performance Band Guide With Servo Feed System

Experience precision cutting with our high-performance band guide featuring a servo feed system. Engineered for optimal accuracy, this advanced technology ensures smooth and consistent material feed, enhancing cutting efficiency and reducing waste.

Feed Gripper With Ball Screw and Servo Motor

Elevate your cutting precision with our feed gripper equipped with a ball screw and servo motor. Designed for seamless material handling, this advanced system ensures smooth and precise feeding, enhancing cutting accuracy and efficiency.

Intelligent Control System

Intelligent control system harnesses advanced algorithms and machine learning to autonomously manage and optimize processes, devices, or systems.

Efficient Chip Conveyor With Integrated Coolant Tank

Efficient chip conveyor with an integrated coolant tank is a streamlined solution designed to remove metal chips from machining operations while recycling coolant.

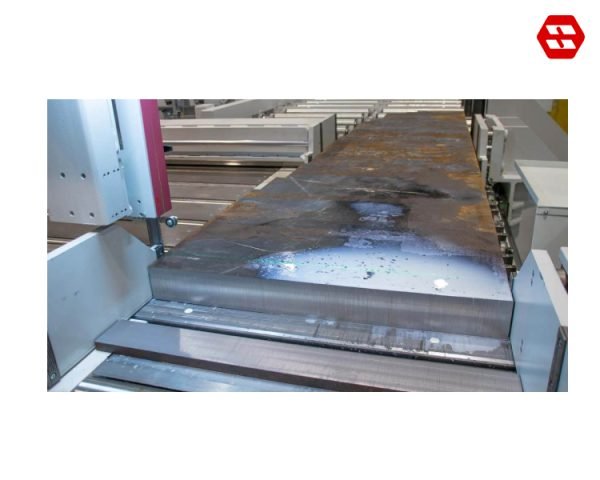

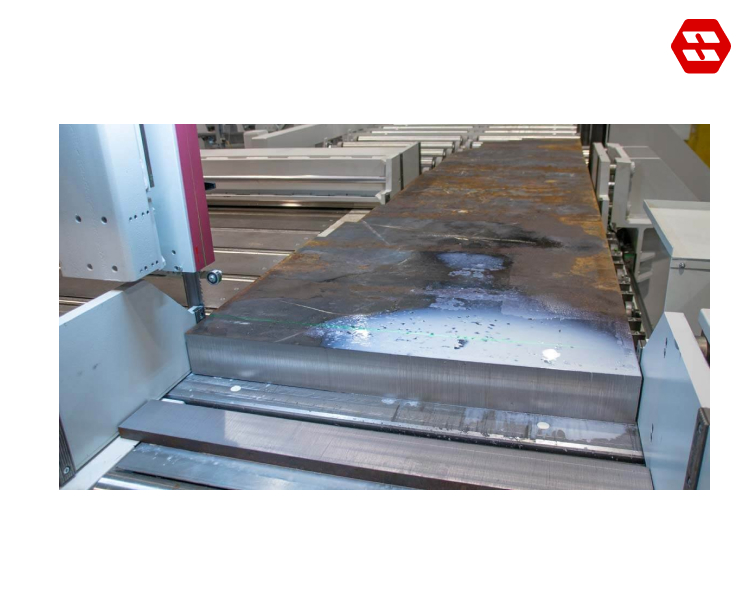

Covered Material Support

Covered material support is a protective platform or structure designed to hold and safeguard materials during storage or transport.

Unsurpassed Precise Cross Cutting Plate Saw

Unparalleled precise cross-cutting plate saw, engineered to deliver unmatched accuracy and efficiency. Ideal for demanding industrial applications, this cutting-edge machine ensures precise cuts across a wide range of materials with exceptional reliability.

Features of The Automatic Plate Saw VPS60-160A

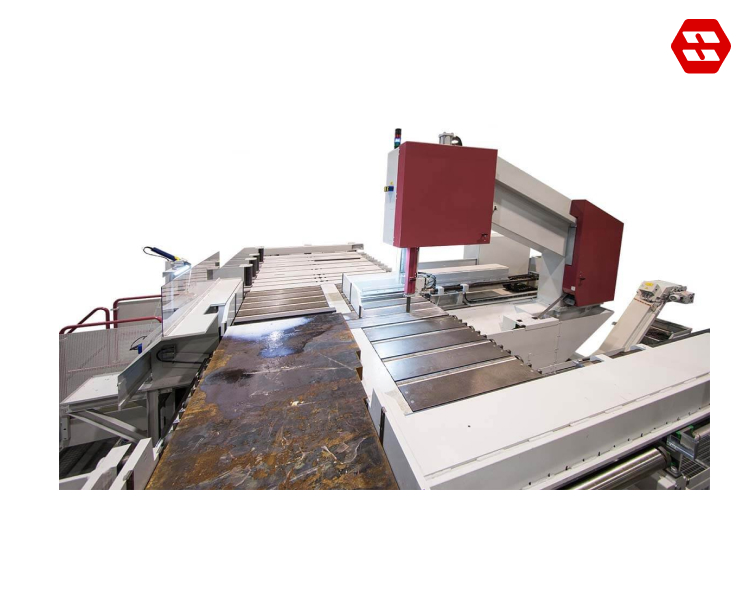

Vertical Arrangement of The Saw Band.

Reduces the engagement length when sawing wide slabs and plates. Compared to horizontal band saws, smaller and finer toothed bandsaw blades can be used.

Unsurpassed Precision and Cutting Performance.

The high cutting accuracy, quiet running and long blade life are all down to the special torsion resistant design of the saw frame.

Powered Duplex Chip Brushes.

Optimum sawing result without any adjustments - the moving band guide is automatically adjusted to the cutting height.

Powered Duplex Chip Brushes.

Actively clean the blade and prevent chips being drawn into the cutting channel.

High-Performance Sawing Unit.

In a torsion-resistant C-frame design makes up the core of the system. The direct guidance of the saw frame close to the work area allows for better cutting performance and low vibrations.

Servo Feed System.

The BEHRINGER servo feeding system ensures constant chip removal and makes better use of the capabilities of modern bandsaw blades.

Economical use of Carbide Saw Blades.

Due to robust design, use of latest servo technology and well dimensioned chip disposal.

Cast Iron Band Guiding Parts.

Are made by BEHRINGER and provide vibration damping directly at the cutting edge, thus increasing tool life.

Optimum Accessibility.

BEHRINGER attaches great importance to the aspect of maintenance and servicing: All the important parts and components are very accessible.

Chip Conveyor Standard.

A generously sized chip conveyor with integrated coolant tank is located under the saw unit, directly in the chip flow direction.

Easy to use.

Quick and easy operation of all functions via touch control.

Technical Data Automatic Plate Saw VPS60-160A

| Cutting Range | |

| Cutting range flat W x H | 1,600 x 600 mm |

| Smallest dimension to be sawn flat W x H | 500 x 20 mm |

| Shortest cutting length | 15 mm |

| Performance Characteristics | |

| Feeding length single stroke | 1,500 mm |

| Drive power | 7.5 kW |

| Blade speed | 17 – 120 m/min |

| Saw blade dimensions | 10,070 x 54 x 1.6 mm |

| Rest piece length in automatic operation | 40 mm |

| Total power | 15 kW |

| Saw feed | servo-feed via pinion gear |

| Material feed | ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimensions and Weight | |

| Length | 10,900 mm |

| Width | 3,600 mm |

| Height | 4,220 mm |

| Weight | 17,000 kg |

| Material support height | 1,620 mm |