Description

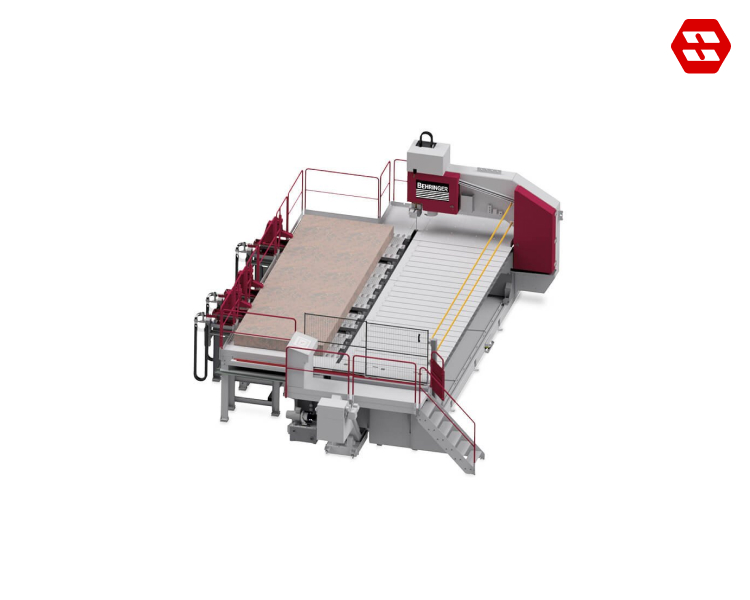

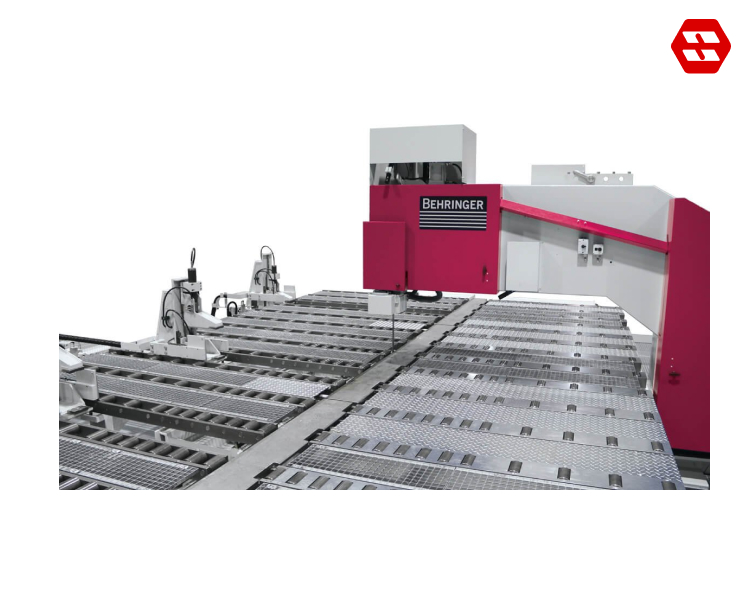

Vertical Bandsaw LPS40-160-4A

Completely automated plate cutting, particularly within the steel trade sector, is simplified with the LPS40-160-4A automatic plate saw. This machine provides an optimal solution for producing parts directly from plates in a single setup, eliminating the need for manual plate rotation. Utilizing a 90° rotating band guide, the vertical bandsaw effortlessly executes both longitudinal cuts and the sawing of finished parts without requiring manual material handling.

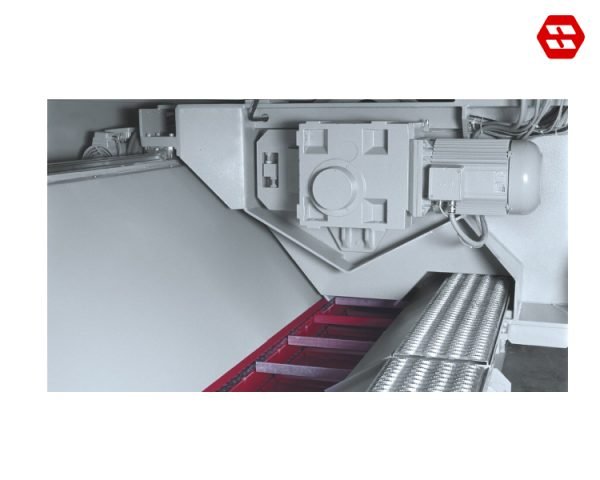

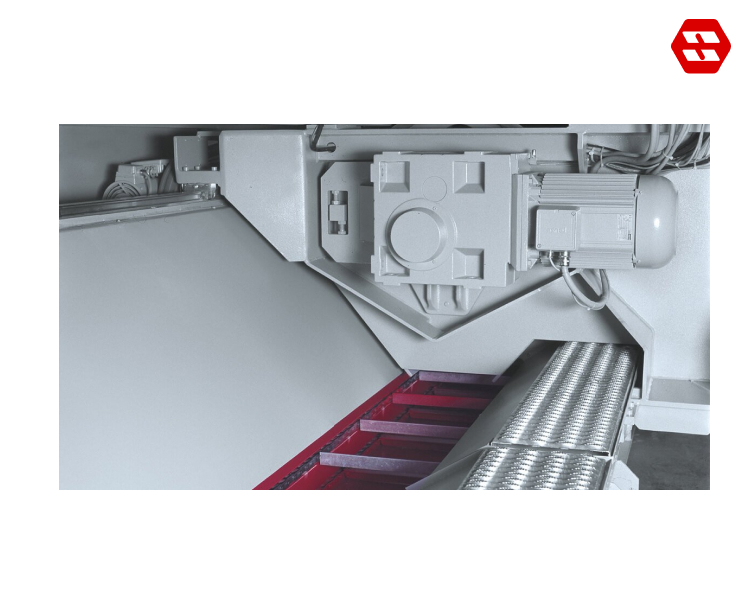

Servo Feed System

The BEHRINGER servo feeding system ensures constant chip removal and makes better use of the capabilities of modern bandsaw blades.

Table Variant With Rollers on The Inner Table

Table variant featuring rollers on the inner table, designed for enhanced material handling and maneuverability. Ideal for industrial applications, this configuration offers smooth and efficient movement of workpieces, optimizing workflow and productivity.

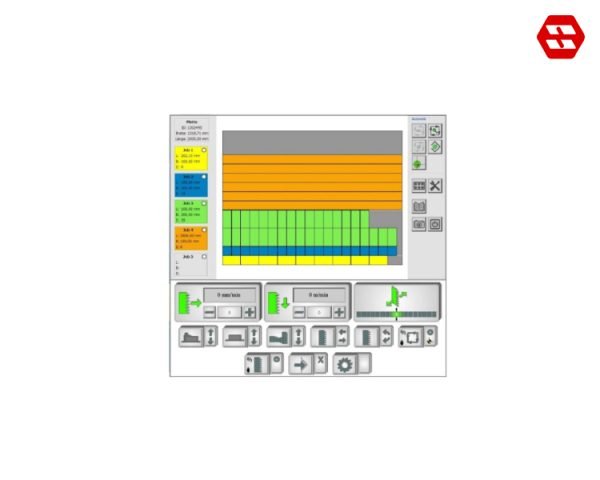

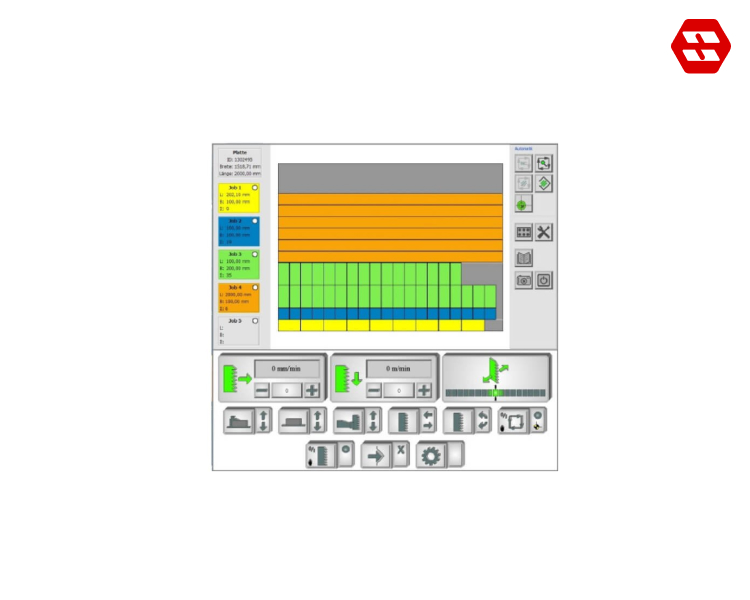

System Control / Plate Editor

Benefit from intuitive system control with touchscreen. The jobs are entered into the plate editor and clearly displayed in the working area. The raw plate dimensions are measured fully automatically through standard plate contour detection.

Features of The Automatic Vertical Bandsaw LPS40-160-4A

High Degree of Automation.

BEHRINGER LPS automatic machines offer fully automated order processing with optional 90° rotatable band guides, enabling seamless production of customer-specific dimensions.

Advantages in Material Purchasing.

By producing flat materials from large sheets, rationalisation effects can be achieved both in warehousing and in the purchase of raw materials.

Quick Bandsaw Blade Change.

Quick and easy – tool-free bandsaw blade changes mean shortest set-up times. Just a few simple steps are all that is needed to change the bandsaw blade of the block saw.

Unsurpassed Precision and Cutting Performance.

The high cutting accuracy, quiet running and long blade life are all down to the special torsion resistant design of the saw frame.

Rotatable Blade Guide.

The LPS automatic machines can be supplied with a blade guide that can be rotated by 90°. This enables the machine to be used for automatic longitudinal and crosswise cutting of plates.

Nesting Functionality.

The optimised arrangement of the sawing jobs is carried out either according to cutting time or waste (rest piece optimisation).

Technical Data Automatic Vertical Bandsaw LPS40-160-4A

| Cutting Range | |

| Cutting length | 4,100 mm |

| Cutting width | 1,600 mm |

| Cutting height | 4,00 mm |

| Minimum cutting width | 30 mm |

| Minimum cutting height | 8 mm |

| Performance Characteristics | |

| Drive power | 7.5 kW |

| Blade speed | 10 – 100 m/min |

| Saw blade dimensions | 8,000 x 54 x 1.6 mm |

| Inside table: | |

| Supporting area | 1,800 x 4,250 mm |

| Outside table: | |

| Supporting area | 1,800 x 4,250 mm |

| Number of grippers | 3 |

| Supporting area inside table | Gripper stroke1,850 mm |

| Dimensions and Weight | |

| Length | 8,250 mm |

| Width | 6,200 mm |

| Height | 4,100 mm |

| Weight | 21,000 kg |

| Material support height | 1,620 mm |