Description

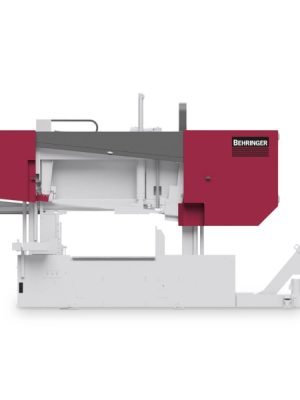

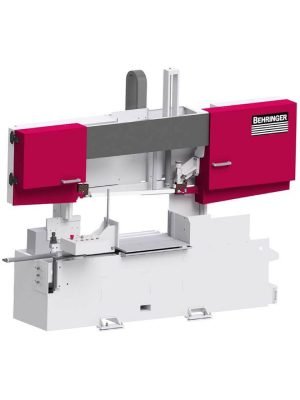

Horizontal Mitre HBE520-926

The HBE520-926G Horizontal Mitre Bandsaw is engineered for automatic cutting of structural steel, profiles, and pipes, boasting high-performance capabilities. It comes equipped with features like electronic mitre angle adjustment, servo motor-driven saw feed, BEHRINGER cutting pressure control, automatic guide arm adjustment, and a sturdy double clamping vice as standard.

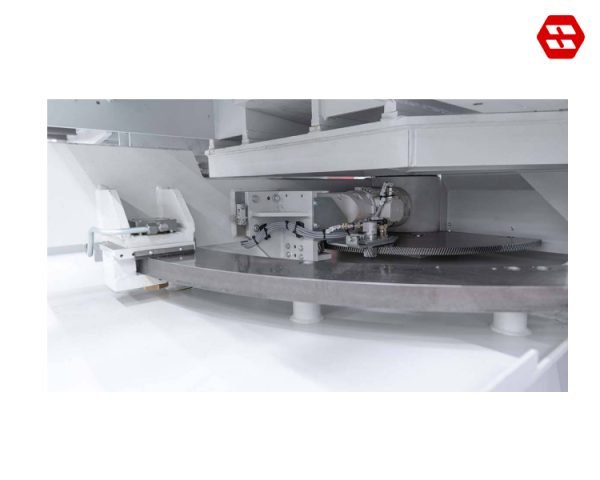

Enclosed Material Table

An Enclosed Material Table offers a secure and organized workspace for handling materials in various industrial applications. With protective barriers or sides, it ensures safety by containing materials within the table area, preventing spills or accidents.

Cast Iron Band Guiding Parts

Are made by BEHRINGER and provide vibration damping directly at the cutting edge, thus increasing tool life.

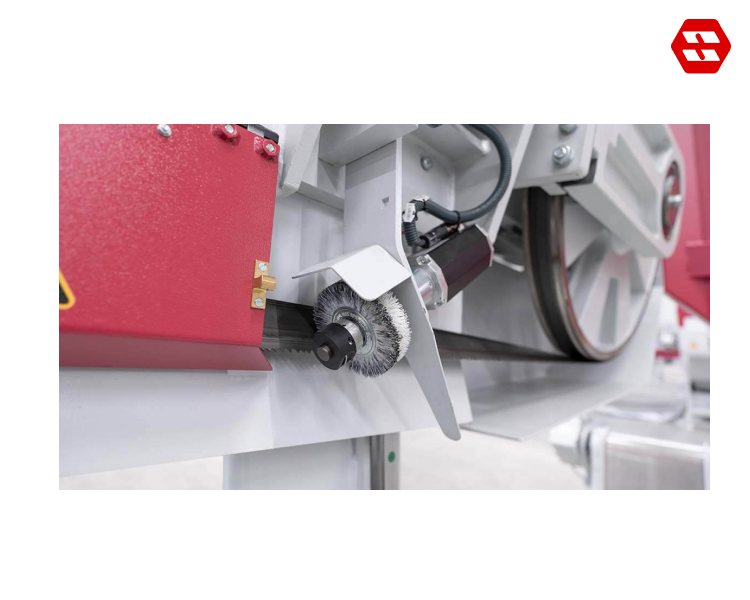

Electrically Driven Chip Brush

With BEHRINGER quick-change device for tool-free brush changes. The teeth of the saw band are protected by the special engagement angle.

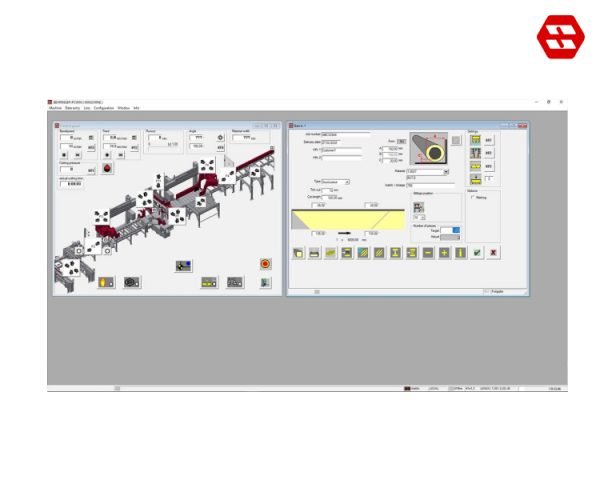

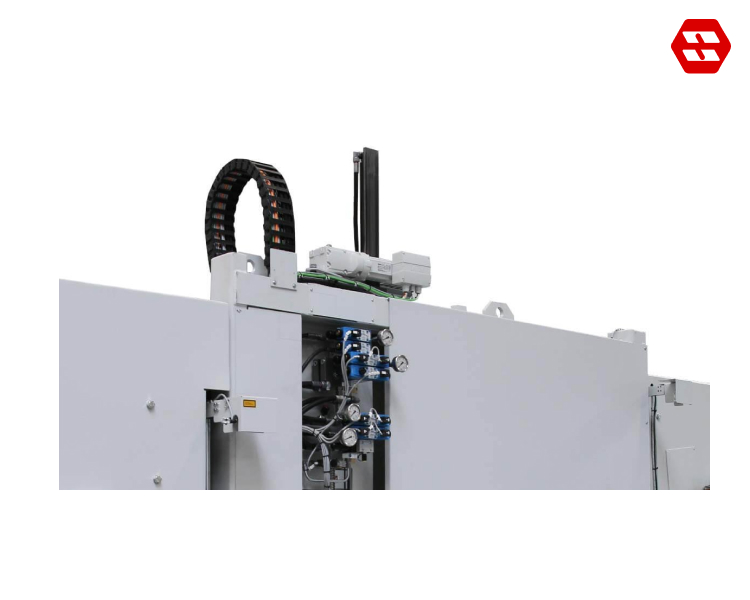

Powerful PC Control

The Powerful PC Control system offers advanced computing capabilities for precise and efficient management of industrial processes. With robust hardware and intuitive software, it enables comprehensive control and monitoring of equipment, ensuring optimal performance and productivity.

Servo Feed System With BEHRINGER Cutting Pressure Control

The Servo Feed System with BEHRINGER Cutting Pressure Control integrates precision servo technology with advanced pressure control by BEHRINGER, enhancing efficiency and accuracy in metal cutting applications. This system ensures consistent and optimized feed rates while dynamically adjusting cutting pressure, resulting in precise and clean cuts across various materials.

Features of The Metal Cutting Bandsaw HBE520 - 926G

Sensitive BEHRINGER Cutting Pressure Control.

Increases the cutting performance when sawing tubes and profiles, as it automatically adapts the saw feed of the machine to the changing material cross-sections.

Precision Portal-Design Guide System.

The combination of stable, low-vibration saw frame and the linear guide system in portal design ensure the best band sawing results and maximum service life.

Safe Material Flow - Even With Short Starting and Cut-off Lengths.

The closed table support and the clever connection to material handling systems offer maximum process reliability in fully automatic operation.

Cast Iron Band Guiding Parts.

Are made by BEHRINGER and provide vibration damping directly at the cutting edge, thus increasing tool life.

Downfeed Control With Servo Drive

The saw feed is carried out by means of a ball screw and servo motor. This results in considerably shorter non-productive times and more precise saw feeds.

Automatic Guide Arm.

Optimum sawing result without any adjustments - even with frequently changing material sizes.

6° Inclination of The Saw Band

Provides significantly higher cutting performance when sawing large beams and hollow profiles and reduces burr formation.

Powerful Saw Drive.

With a wide range of blade speed adjustment offers flexibility for various starting materials from stainless steel to aluminium.

Micro Spray System.

When sawing profiles, pipes and solid material, the standard minimum quantity lubrication system delivers the best results.

Customer-Oriented Sawing Concepts.

BEHRINGER offers complete system solutions with individual material handling where everything fits together perfectly.

Vertical Clamping Device on Both Sides of The Saw Band.

Thanks to the standard combination of horizontal and vertical clamping device, all profile shapes are securely clamped.

Double clamping Vice.

Offers process reliability - especially when sawing bundles or making single cuts.

Technical Data Mitre Bandsaw HBE520-926G

| Cutting Range | |

| Cutting range 90° round | 520 mm |

| Cutting range 90° flat | 920 x 520 mm |

| 75° Mitre left round / flat | 520 mm / 920 x 520 mm |

| 60° Mitre left round / flat | 520 mm / 810 x 520 mm |

| 45° Mitre left round / flat | 520 mm / 640 x 520 mm |

| 30° Mitre left round / flat | 430 mm / 430 x 520 mm |

| 75° Mitre right round / flat | 520 mm / 920 x 520 mm |

| 60° Mitre right round / flat | 520 mm / 810x 520 mm |

| 45° Mitre right round / flat | 520 mm / 640 x 520 mm |

| Smallest dimension to be sawn round | 30 mm |

| Smallest dimension to be sawn flat | 30 x 30 mm |

| Performance Characteristics | |

| Drive power | 5,5 kW |

| Blade speed | 17 – 120 m/min |

| Saw blade dimensions | 8.500 x 54 x 1,6 mm |

| Rest piece length | 45 mm |

| Total power | 11 kW |

| Saw feed | Servo feed via ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimensions and Weight | |

| Length | 1,900 mm (3,950 mm at mitre angle 30°) |

| Width | 4,150mm |

| Height | 2,960 mm |

| Weight | 4,100 kg |

| Material support height | 800 mm |