Description

Cold Saw VMS 370

Classics in any workshop that requires precise metal cuts.The heart of the VMS circular saw is the worm gear unit with EISELE shock-absorbing feature, produced in-house. It is heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface, the blade life and the service life of the saw.

Worm Gearbox From Our Own Production

Our self-produced worm gearbox is a pinnacle of precision engineering and reliability. Crafted in-house with meticulous attention to detail, it offers exceptional performance and durability in various industrial applications.

Speed Selection of The Circular Saw

Speed selection of the circular saw allows users to adjust the rotational speed of the blade to match specific cutting requirements and materials. This feature enhances versatility and efficiency, enabling operators to achieve optimal results for various tasks.

Coolant Device

A coolant device is a vital component in industrial machinery, particularly in metalworking equipment like saws and milling machines. Its primary function is to regulate and maintain the temperature of cutting tools and workpieces during the machining process.

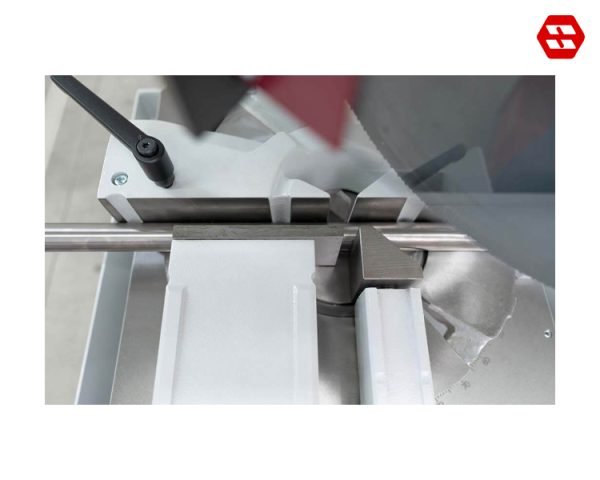

Convenient Mitre Adjustment

Convenient mitre adjustment is a user-friendly feature designed to simplify the process of changing cutting angles on machinery such as saws. With this feature, operators can easily adjust the angle of the cutting blade to achieve precise mitre cuts without the need for complex manual adjustments or additional tools.

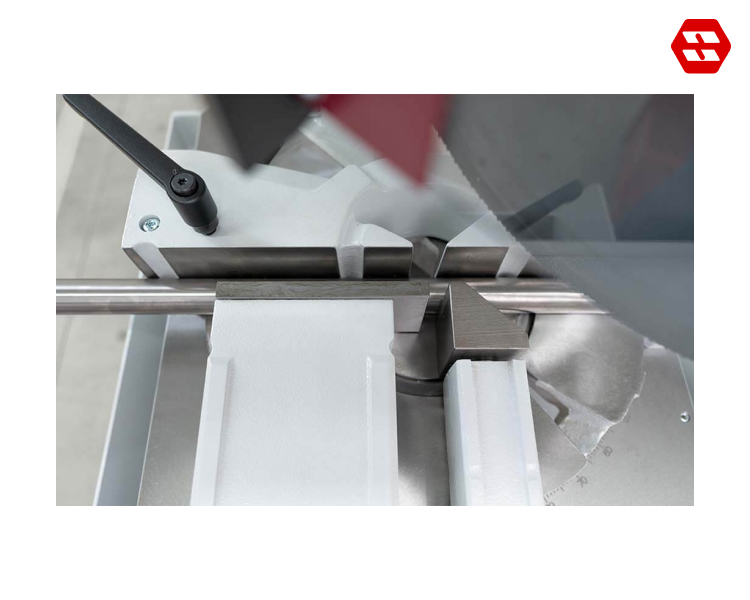

Robust Material Vice

A robust material vice is a sturdy and reliable clamping mechanism commonly used in machinery like saws and milling machines. Engineered from durable materials such as steel or cast iron, it provides secure fixation of workpieces during cutting or machining operations.

Features of The Cold Saw VMS 370

Sturdy Machine Base.

The heavy machine stand and the vibration-damping cast iron components made by BEHRINGER ensure a low-vibration sawing process and thus an increase in tool life.

User Friendly Mitre Adjustment.

This allows changing mitre angles to be set precisely and quickly.

High Flexibility.

The cold saw VMS 350# can be flexibly adapted to your material flow.

Low Space Requirement.

High productivity with simultaneously compact dimensions of less than 1 m².

Saw Feed Via Safety Snap-in Lever.

The saw feed can easily be set to the shortest possible saw travel.

Worm Gear Unit With EISELE Shock-Absorbing Feature.

An ideally designed gearbox from our own production offers long blade life and maximum durability.

Clean Machine Design.

The coolant unit and the chip drawer are integrated into the machine base.

Technical Data Cold Saw VMS 370

| Cutting Range | |

| Flat 90° | 200 x 100 mm |

| Flat 45° | 140 x 100 mm |

| Flat 30° | 100 x 100 mm 1) |

| Square 90° | 120 mm 2) |

| Square 45° | 100 mm |

| Square 30° | 90 mm 1) |

| Round 90° | 130 mm |

| Round 45° | 130 mm |

| Round 30° | 105 mm 1) |

| Performance Characteristics | |

| Drive power | 2.0 / 2.6 kW |

| RPM standard | 17 / 34 – 34 / 68 min-1 |

| RPM optional | 8 / 16 / 32 / 64 min-1 |

| Saw blade diameter | 370 mm |

| Saw feed | manual |

| Material clamping | manual |

| Dimensions and Weight | |

| Length | 1,085 mm |

| Width | 865 mm |

| Height | 1,800 mm |

| Weight | 430 kg |

| Material support height | 900 mm |