Description

Automatic Mitre Circular Saw PSU 450 A

Its robust construction and advanced features ensure clean and efficient cuts, making it ideal for a variety of metal fabrication applications. Whether for industrial manufacturing or fabrication projects, the PSU 450 A enhances productivity and quality, making it an indispensable tool in your workshop.

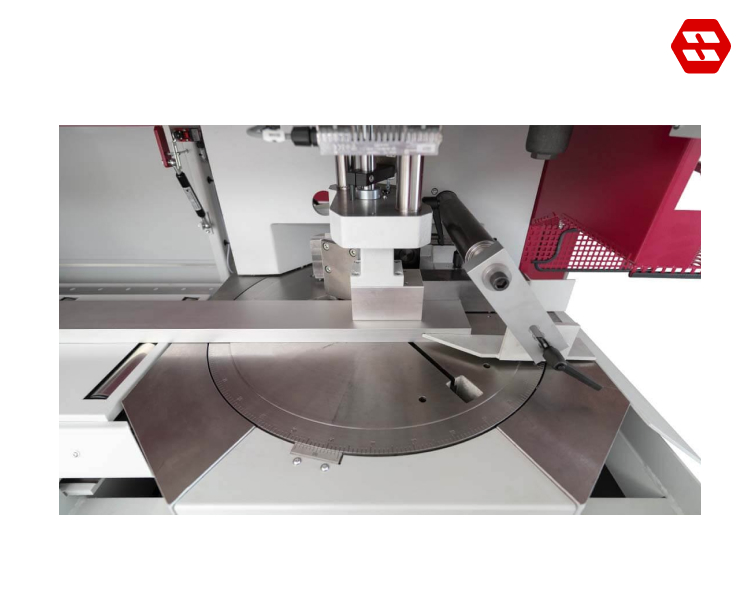

Automatic Mitre Adjustment 30° to 150°

Achieve precision and versatility effortlessly with our Automatic Mitre Adjustment feature, spanning from 30° to 150°. This cutting-edge capability eliminates manual adjustments, allowing seamless transitions between various cutting angles.

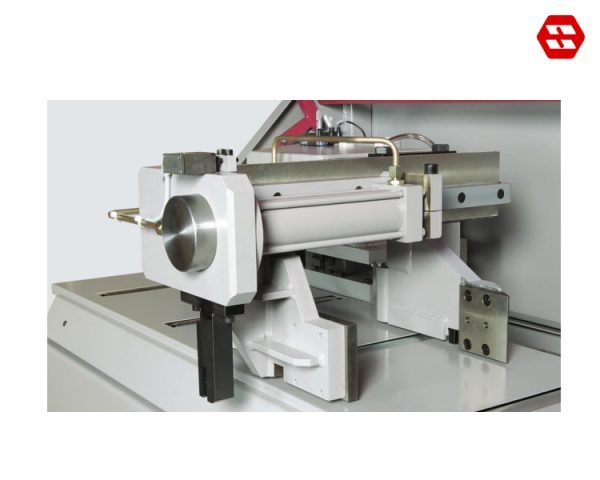

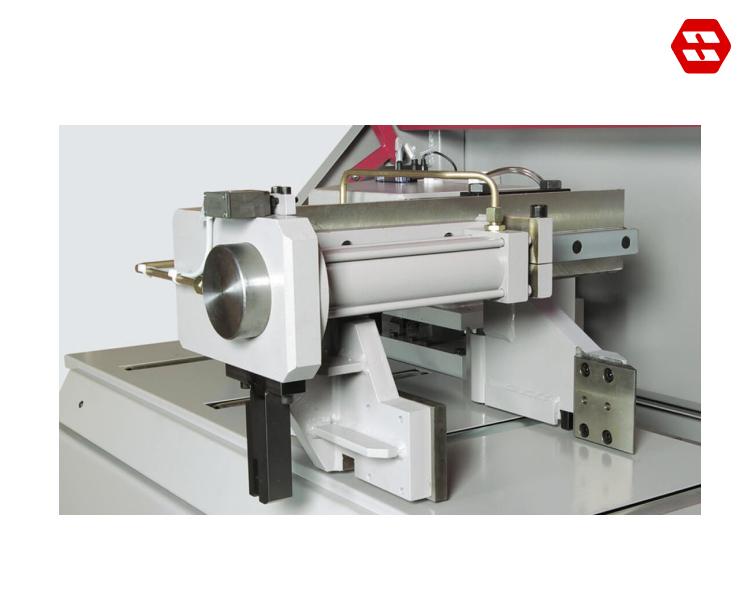

Servo-Driven Feeding Gripper

Enhance precision and efficiency in your metalworking processes with our Servo-Driven Feeding Gripper.With its servo-driven mechanism, it offers superior accuracy and reliability, allowing for consistent performance in demanding manufacturing environments.

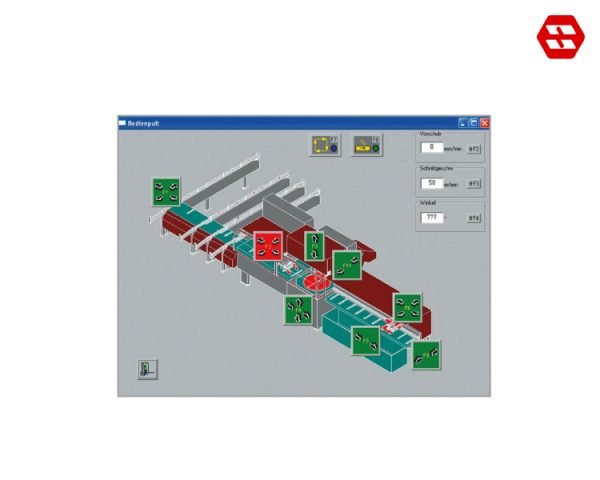

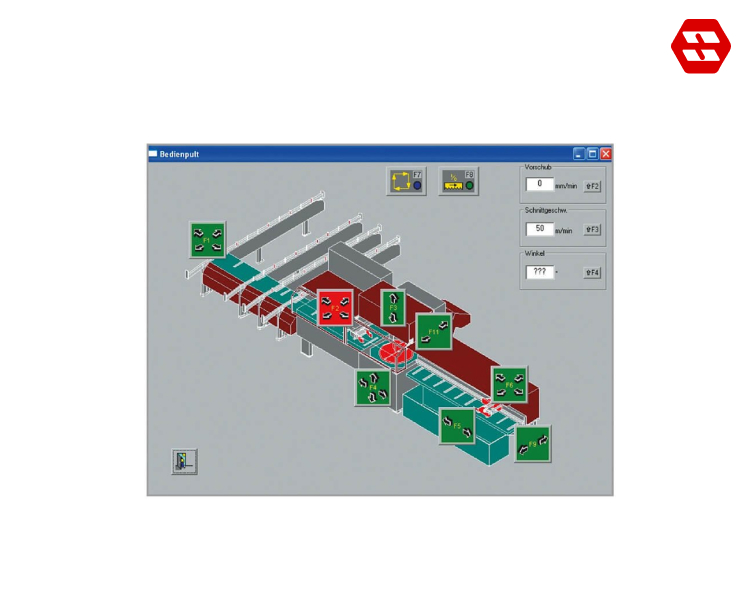

Powerful Control

Experience unparalleled command over your metalworking processes with our Powerful Control system. With its intuitive interface and robust capabilities, our control system empowers operators to optimize performance and achieve superior results with ease.

Highest Level of Automation With Cut-Off Gripper

Experience the pinnacle of automation with our Circular Saw Machine equipped with the Cut-Off Gripper. This innovative system offers unparalleled efficiency and precision in metal cutting tasks.Streamline your operations and elevate your efficiency with our Cut-Off Gripper-equipped Circular Saw Machine.

Features of The Mitre Circular Saw PSU 450 A

Micro Spray System.

When sawing profiles, pipes and solid material, the standard minimum quantity lubrication system delivers the best results. The saw blade is constantly moistened with cutting oil via a nozzle.

Robust and Durable.

The heart of the PSU saw units is a worm gear unit with EISELE shock-absorbing feature, produced in-house. The robust design of the gearbox consistently dampens vibrations.

Optimum Chip Flow.

Also when sawing tubes and hollow profiles due to the saw feed from bottom up.

Modern Interfaces.

The connection of the sawing system to process control systems can be realised via standardised interfaces such as ASCII, DSTV or OPC-UA.

Extensive Range of Materials.

The mitre circular saws of the PSU series cover an extensive range of materials such as flat, angular and solid material, pipes and special profiles.

Simple,Intuitive Control.

Everything in view. Everything under control. The control system is self-explanatory, simple, avoids operating errors and allows quick navigation in the various programmes.

Short Cycle Times.

by electronic cutting height adjustment and rapid return of the saw blade.

Highest Level of Automation.

By connecting the infeed and cut-off gripper, the mitre circular saw is fully automated.

Sturdy Machine Base.

The heavy machine stand and the vibration-damping cast iron components made by BEHRINGER ensure a low-vibration sawing process and thus an increase in tool life.

Reduced Material Consumption.

Alternating sawing eliminates the need for gussets on sections with the same angle. This saves material and increases productivity.

High Cutting Quality.

Workpiece clamping on both sides of the saw blade ensures a clean cutting surface and low tolerances.

Servo Axes.

For precise and fast length positioning of the starting material and mitre angle adjustment.

Technical Data Mitre Circular Saw PSU 450 A

| Cutting Range | |

| Flat 90° | 240 x 70 mm |

| Flat 45° | 170 x 50 mm |

| Flat 30° | 130 x 30 mm |

| Square 90° | 140 x 140 mm |

| Square 45° | 125 x 125 mm |

| Square 30° | 100 x 100 mm |

| Round 90° | 150 mm |

| Round 45° | 145 mm |

| Round 30° | 112 mm |

| Smallest dimension to be sawn round | 10 mm |

| Smallest dimension to be sawn flat | 10 x 10 mm |

| Performance Characteristics | |

| Drive power | 7,1 kW |

| RPM | 1 – 70 min-1 |

| Saw blade diameter | 450 mm |

| Feeding length single stroke | 1,500 mm |

| Feed rate | 667 mm/s |

| Saw feed | hydraulic |

| Material clamping | hydraulic |

| Dimensions and Weight | |

| Length | 5,800 mm |

| Width | 1,600 mm |

| Height | 2,300 mm |

| Weight | 3,150 kg |

| Material support height | 1,045 mm |